Cylindrical Dripper Drip Irrigation Pipe Production Line

The ultra high-speed production speed can reach more than 120 meters per minute, bringing super higher capacity to your production. More than 600 drippers are delivered per minute, making production efficiency twice as good with half the effort.

Classification:

Key words:

Cylindrical dripper irrigation pipe machine

Cylindrical dripper irrigation pipe extrusion line

Cylindrical dripper irrigation pipe production line

Dripper production equipment

Strip-type dripper production line

More products please click directory to download:

Description

Technical Parameters

| Pipe Diameter | Pipe Thickness | Normal Production Speed | Dripper Spacing |

| Φ12-16-20-22-25 | 0.5-1.5mm (Optional) |

30m~80m/min | 100, 150, 200, 300, 400, 500, 1000mm |

Production Introduction: Cylindrical Dripper Drip Irrigation Pipe Production Line

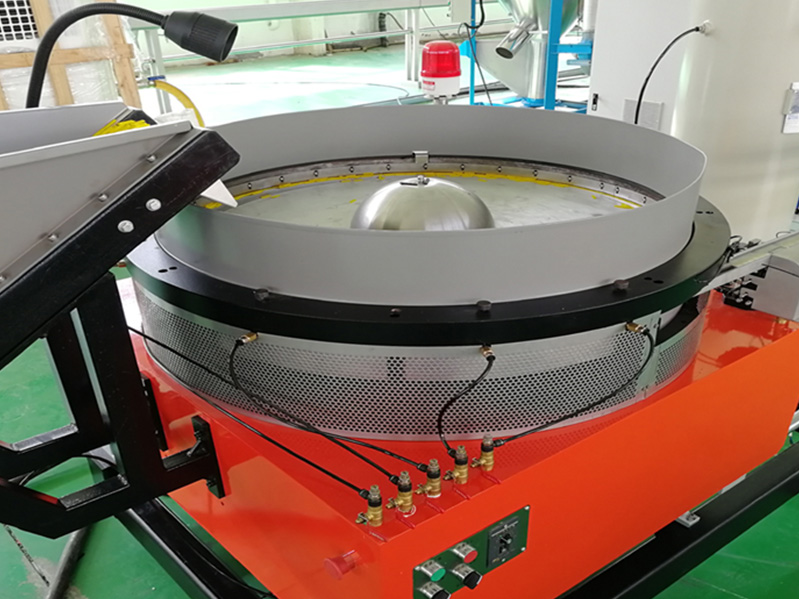

Core Component 1: Dripper Screening Device

- High-Speed Dripper Screening and Insertion System: Capable of efficiently screening and inserting cylindrical drippers at a rapid pace.

- Versatile Dripper Compatibility: Designed to handle cylindrical drippers of various sizes, including 12mm, 16mm, and 20mm.

- Insertion Speed: Achieves an impressive insertion speed of 400 pieces per minute, ensuring high productivity.

- Precision Servo-Driven Control: Equipped with a servo-driven system for precise control over the dripper insertion process, ensuring accuracy and reliability.

Core Component 2: Single-screw Extruder

The machine nose adopts single layer spiral structure, the inner pressure is uniformity, which could improve the flow property of the plastic, the gloss of the products and the wall thickness uniformity, which is suitable for the high speed production of the thin wall pipe.

Core Component 3: Punching and HD Punching Visual Detection Device

- Automatic Punching Technology: Incorporates advanced automatic punching technology for efficient operations.

- High-Speed Punching: Achieves a Punching speed of 400 pieces per minute, maximizing productivity.

- Versatile Hole Configurations: Capable of Punching double holes or four holes as per requirements.

- Precision Control: Controlled by servo motors to ensure precise drilling, maintaining accuracy and consistency.

- Remote Support Service: Offers customers remote support services for assistance and troubleshooting, ensuring smooth operations and maintenance.

Core Component 4: Thick Wall Dedicated Automatic Winding Device

Automatic roll change, automatic bundling, and winding speed up to 150m/min;

Imported AC servo motor is used to ensure the stability of winding;

Control the operation through the PLC man-machine interface.

Reference Video: Ultra high-speed cylindrical drip irrigation pipe production line

Previous Page

Related Products

Messages

We will contact you within one working day. Please pay attention to your email.