Inlaid Pressure Compensating Drip Irrigation Pipe Production Line

Core Component :Dripper Screening Device,Dripper Conveyor,Single-screw Extruder,Punching and HD Punching Visual Detection Device,Thick Wall Dedicated Automatic Winding Device.

Classification:

Key words:

Drip Irrigation Pipe Production Line

Inlaid PC dripper

Strip-type dripline production line

More products please click directory to download:

Description

Production Introduction

|

Pipe Diameter |

Pipe Thickness |

Dripper Spacing |

Normal Production Speed |

|

Ф16 mm |

0.4mm |

300mm |

140m/min |

|

0.6mm |

300mm |

120 m/min |

|

|

0.8mm |

300mm |

100 m/min |

|

|

1.0mm |

300mm |

90 m/min |

Production Introduction: Inlaid Flat Dripper Pressure Compensation Drip Irrigation Pipe Production Line

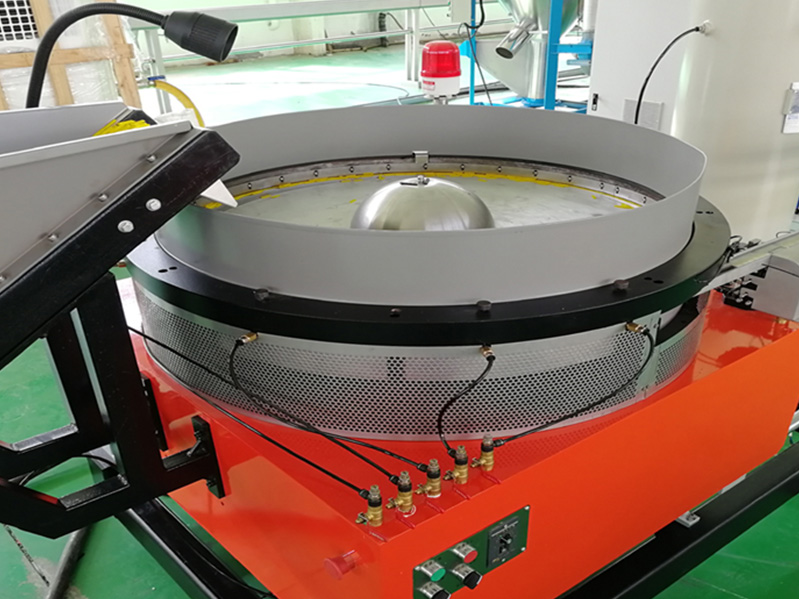

Core Component 1: Dripper Screening Device

Equipped with advanced dripper conveying and storage device, automatic dripper screening, 1500W screening motor, two selection discs with diameters of 1000mm and 1280mm, and the screening speed is 800-1200 pieces/min and 1200-1500 pieces/min respectively.

Core Component 2: Dripper Conveyor

The pathway is drawing forming by aluminum alloy, which ensures smoothing the high speed delivery of drippers, it is convenient for changing the wear parts.

Adopt the AC servo motor, which ensures the stability of the drippers delivery.

The loading device is controlled by servo-system,which ensures the dripper to maintain their set space according to the changeable speed of the dripping tube at any time.

Core Component 3: Single-screw Extruder

The machine head adopts a single-layer spiral structure, and the internal pressure is uniform, which improves the fluidity of the plastic, the gloss of the product and the uniformity of the wall thickness, which is suitable for the high-speed production of thick-walled pipes;

At the same time, the co-extrusion compound unit composed of two extruders can realize the production of double-layer composite pipes.

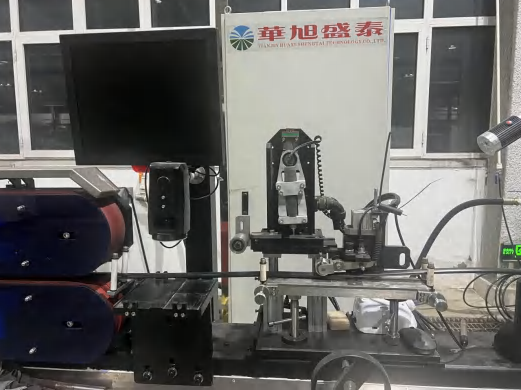

Core Component 4: Punching and HD Punching Visual Detection Device

Fully automatic punching device, maximum punching speed > 1000 pieces/minute;

Equipped with advanced punching visual inspection device, which could automatically inspect the punching effect. Timely find the situation of deviation, missed hit, or no chips, and report to the alarm in time.

Real-time tracking and adjustment of punching status through PLC control screen.

Core Component 5: Thick Wall Dedicated Automatic Winding Device

Automatic roll change, automatic bundling, and winding speed up to 150m/min;

Imported AC servo motor is used to ensure the stability of winding;

Control the operation through the PLC man-machine interface.

Reference Video: Inlaid Pressure Compensating Drip Irrigation Pipe Production Line

Previous Page

Related Products

Messages

We will contact you within one working day. Please pay attention to your email.