Inlaid T-tape drip irrigation pipe production line

T-tape dripper enhances uniformity of flow significantly compared to flat drippers and normal labyrinth irrigation pipes. Moreover, it boasts a clear advantage in anti-blocking capabilities.

Classification:

Key words:

T-tape Drip Irrigation Pipe Production Line

Water saving drip irrigation tape

Drip irrigation tape production line equipment

Irrigation tape system

Drip tape for irrigation

Pressure compensating drip tape

More products please click directory to download:

Description

Technical Parameters

|

Pipe Diameter |

Pipe Thickness |

Normal Production Speed |

Dripper Spacing |

|

Φ12-16-20-22-25 |

0.18-0.2mm |

150m~200m/min |

/ |

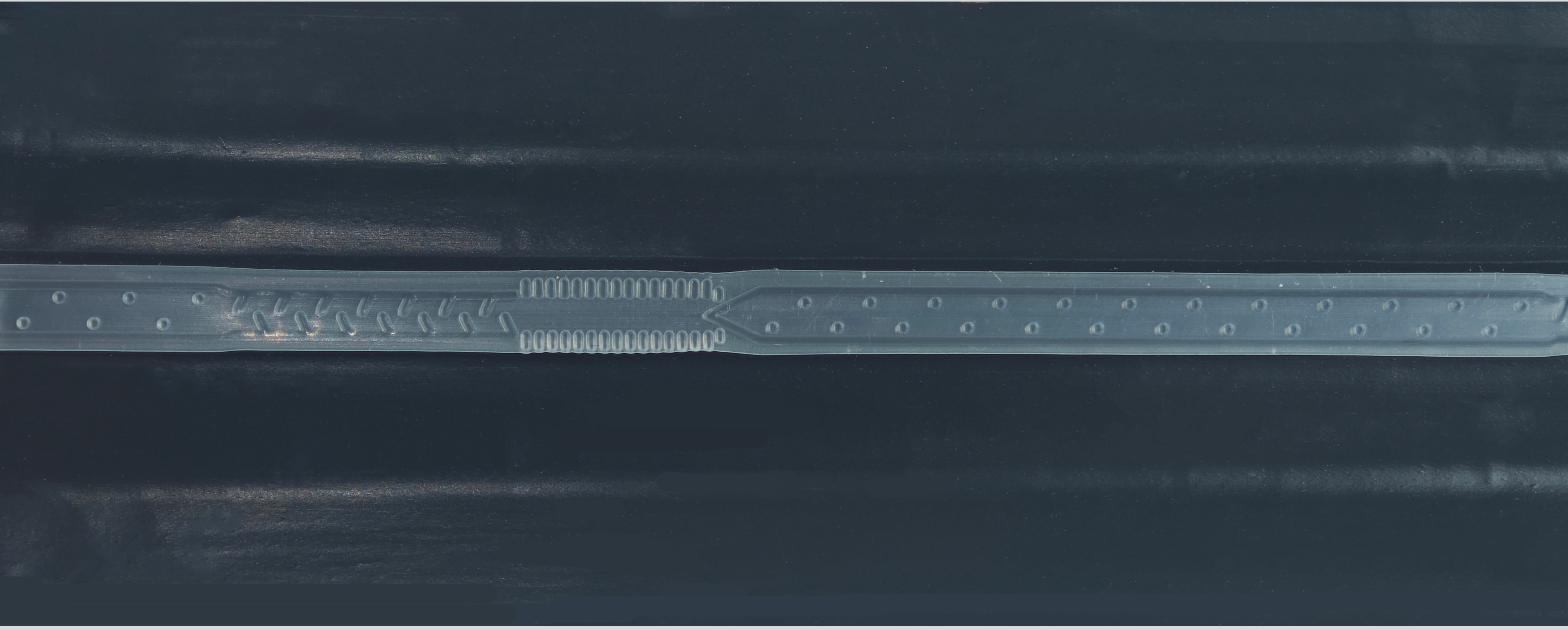

Inlaid T-tape dripper is designed with a turbulent flow that is long enough to produce a damping effect and reduce pressure. This design enhances uniformity of flow significantly compared to flat drippers and normal labyrinth irrigation pipes. Moreover, it boasts a clear advantage in anti-blocking capabilities. The water outlet employs a slit-type construction similar to a one-way valve, shutting off water flow when negative pressure occurs in the pipe. This prevents the absorption of soil from the field and prevents clogging by grass roots due to negative pressure.

1.Exceptionally high irrigation uniformity and superior flow index offer hydraulic performance beyond comparison with other types of irrigation pipes.

2.Extrusion welding forms the pipe in one piece, eliminating joints and rough edges, reducing the risk of bursting under compression.

3.Numerous filter holes at the inlet ensure high resistance to clogging.

4.The outlet features machine-perforated slots, preventing intrusion of plant roots and insects that could block the dripper. Its anti-blocking performance surpasses other types due to its special outlet design.

5.The extended turbulent flow and good flow index facilitate excellent energy dissipation and offer certain compensation.

6.The exclusive double blue stripe makes it easier to identify during installation.

7.Available in various pipe diameters and thicknesses, with certain compensation, allowing for longer laying lengths.

Production Introduction: Inlaid T-tape Drip Irrigation Pipe Production Line

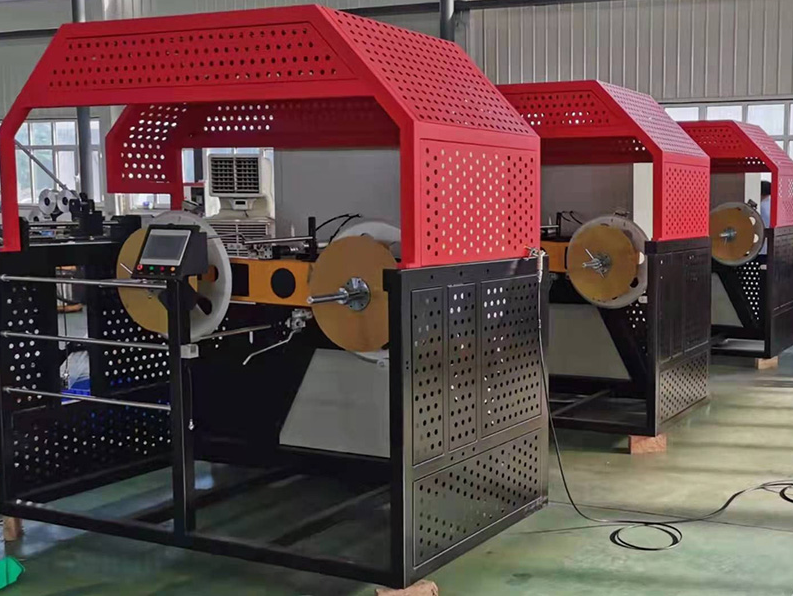

Core Component 1: T-tape Dripper Shapping Device

Inlaid T-tape dripper ensures precise formation of internal labyrinth strips, crucial for water flow accuracy.

1.Thermoforming Technology: The inlaid labyrinth T-tape drippers are thermoformed with precision, guaranteeing exact water flow.

2.Servo Motor Control: The inlaid labyrinth T-tape dripper shapping device is equipped with servo motor control, ensuring efficient operation and adaptability.

3.Customizable Flow: Easily adjustable to accommodate clients' required flow rates, facilitating versatility in usage.

4.Special Technologies: Incorporates advanced internal cooling systems to ensure continuous strip production and high-speed molding, enhancing productivity and reliability.

Core Component 2: Punching and HD Punching Visual Detection Device

Fully automatic punching device, maximum punching speed > 2600pieces/minute;

Equipped with advanced punching visual inspection device, which could automatically inspect the punching effect. Timely find the situation of deviation, missed hit, or no chips, and report to the alarm in time.

Real-time tracking and adjustment of punching status through PLC control screen.

Core Component 3: Double Position Winding Machine

Automatically completes the rewinding, rewinding and switching of the drip irrigation pipe, and the maximum rewinding speed can reach 400m/min.

Imported AC servo motor is selected to ensure the stability of winding.

Control the operation through the PLC man-machine interface.

Reference Video: Inlaid T-tape Drip Irrigation Pipe Production Line

Related Products

Messages

We will contact you within one working day. Please pay attention to your email.